Exploring the detailed production process behind Rubber Keypads and their role in modern devices

A Comprehensive Overview to the Manufacturing and Processing of Rubber Keypads for Optimal Efficiency

The manufacturing and handling of rubber keypads play a crucial duty in their performance and use. Material choice, style precision, and innovative production techniques greatly impact their durability and performance. Comprehending these elements is essential for creating top notch items. As numerous advancements arise in this field, exploring their effects could expose brand-new criteria for functionality and user experience. What essential elements will shape the future of rubber keypads?

Comprehending Rubber Keypads: Materials and Kinds

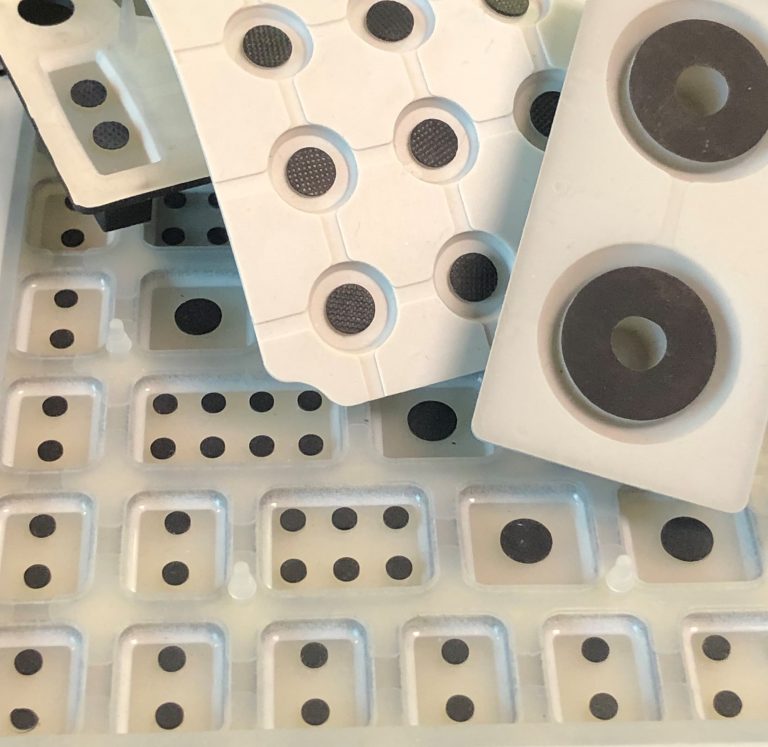

Rubber keypads are vital parts in plenty of tools, using a balance of durability and responsive responses. These keypads are mainly made from silicone or synthetic rubber, products picked for their versatility and strength. Silicone rubber, specifically, is favored for its exceptional temperature level resistance and longevity, making it ideal for various applications, from consumer electronics to industrial machinery.

There are a number of sorts of rubber keypads, consisting of dome switch keypads, which utilize a dome-shaped system that supplies tactile feedback when pushed. In addition, there are likewise level keypads, which include a smooth surface and are commonly used in medical gadgets and remote controls. The choice of product and kind influences the keypad's performance, really feel, and total individual experience. Recognizing these elements is vital for makers and designers aiming to create trustworthy and reliable interfaces in their products.

The Manufacturing Process: From Style to Production

The production procedure of rubber keypads includes a number of crucial stages, beginning with style and ending with manufacturing. Designers produce detailed requirements and models, guaranteeing the keypad satisfies aesthetic and practical needs. Computer-aided design (CAD) software program is commonly used to visualize the layout and functions before continuing.

As soon as the design is completed, material selection is essential, with alternatives generally consisting of silicone or all-natural rubber. In the following stage, mold and mildews are produced based upon the authorized designs, which will form the keypads throughout manufacturing.

Complying with mold creation, the manufacturing stage starts, where rubber is combined with ingredients to improve efficiency. The combination is after that poured right into mold and mildews and based on warm and stress, enabling it to strengthen and treat.

Ultimately, the finished keypads undertake high quality checks to verify they satisfy recognized requirements, adhered to by product packaging for circulation. This all-encompassing process warranties peak efficiency in the final item.

Key Methods in Rubber Molding

In the domain of rubber keypads, different molding techniques play a crucial duty in identifying the top quality and functionality of the end product. One widespread technique is compression molding, where raw rubber is positioned in a warmed mold and mildew and stress is applied, permitting effective mass production and uniformity. An additional significant technique is injection molding, which includes injecting warmed rubber into a mold and mildew, using higher accuracy and complicated shapes. Transfer molding, a crossbreed of both approaches, is also utilized, specifically for elaborate designs, as it combines the benefits of both procedures. In addition, liquid silicone rubber (LSR) molding is getting traction as a result of its adaptability and durability, making it excellent for high-performance applications. Each strategy has special characteristics, affecting aspects such as cycle time, product waste, and production costs. Picking the suitable molding method is necessary for accomplishing peak performance in rubber keypads.

Surface Finishing and Texturing Options

Surface area completing and texturing choices play a crucial duty in improving the responsive experience and aesthetic appeal of rubber keypads. Producers utilize various strategies to create distinct surface characteristics that influence user communication and product design. Usual finishing approaches consist of matte, glossy, and satin finishes, each offering various visual impacts and grip degrees. Texturing choices, such as raised patterns, grooves, or stippling, even more boost capability by boosting grip and minimizing slippage during usage.

Additionally, specific structures can be tailored to satisfy ergonomic requirements, providing convenience during long term usage. The choice of surface area finishes and textures can be influenced by the intended application of the keypad, whether it be for customer electronic devices, automobile controls, or commercial devices. Eventually, careful factor to consider of these choices contributes greatly to customer satisfaction and overall item performance, making them crucial aspects in the layout and manufacturing procedure of rubber keypads.

Quality Control Procedures in Rubber Keypad Manufacturing

Quality control steps in rubber keypad manufacturing are important for ensuring item reliability and efficiency. These steps incorporate material selection criteria, strenuous testing procedures, and rigorous last evaluation standards. With each other, they develop an extensive framework that aids producers support high quality throughout the manufacturing procedure.

Material Selection Criteria

Selecting the suitable products for rubber keypads is important, as it directly impacts their toughness, individual, and functionality experience. Secret standards for product choice include tensile stamina, resilience, and environmental resistance. The selection of rubber compound, such as silicone or thermoplastic elastomer (TPE), plays an essential function in accomplishing wanted tactile comments and durability. In addition, elements like chemical compatibility, temperature stability, and UV resistance must be thought about to guarantee maximum efficiency in various applications. Makers need to additionally review the convenience of important source processing and cost-effectiveness of materials, balancing top quality with spending plan restrictions. Inevitably, the right product choice not just boosts the keypad's performance but also adds to total item high quality and customer complete satisfaction.

Examining Treatments Executed

After determining the proper materials for rubber keypads, strenuous screening treatments are executed to verify that the last items fulfill market criteria and customer expectations. These procedures normally consist of mechanical testing, which assesses the toughness and flexibility of the rubber under numerous problems. Additionally, environmental testing evaluates the keypads' performance under temperature changes, humidity, and exposure to chemicals. Electrical testing validates the keypads operate properly with electronic components, validating responsiveness and conductivity. Furthermore, responsive feedback is evaluated to assure individual complete satisfaction. These substantial screening measures are crucial in recognizing any kind of issues or incongruities before mass manufacturing, eventually enhancing the dependability and performance of rubber keypads in their intended applications.

Final Inspection Specifications

Comprehensive last inspection criteria are vital in rubber keypad manufacturing to guarantee that each device satisfies the defined requirements for capability and appearance. This process usually includes aesthetic analyses to determine any surface flaws, such as staining or flaws. In addition, tactile examinations determine that the keypads react accurately to touch, keeping the required level of level of sensitivity. Sturdiness examinations may also be conducted, replicating extended usage to verify the long life of the keypad under various problems. In addition, adherence to industry policies and customer specifications is confirmed to keep quality control. By applying these rigorous assessment actions, manufacturers can considerably decrease the danger of problems, guaranteeing that the final product is dependable and meets customer assumptions, eventually improving customer contentment.

Technologies in Rubber Keypad Modern Technology

As modern technology proceeds to develop, innovations in rubber keypad innovation are reshaping interface across different industries. One significant development is the integration of capacitive touch sensing units within rubber keypads, permitting a more receptive and functional individual experience. This innovation enables customers to engage with gadgets through touch, enhancing capability without giving up the responsive responses that rubber keypads are understood for.

Additionally, improvements in product formulas have actually brought about the growth of more resilient, weather-resistant rubber, making keypads suitable for outside and commercial usage. Boosted printing methods likewise enable high-resolution try this web-site graphics and backlighting choices, increasing presence and aesthetic allure.

Innovations in manufacturing procedures, such as 3D printing, are enabling custom-made layouts and quick prototyping, streamlining production timelines. These innovations jointly add to extra effective and straightforward rubber keypads, guaranteeing they fulfill the needs of modern applications while link preserving their core benefits.

Best Practices for Layout and Functionality

Creating effective rubber keypads requires careful assessment of both appearances and capability. Rubber Keypads. A properly designed keypad should balance ergonomic principles with visual interest improve customer experience. Key elements include size, shape, and spacing of switches, ensuring they are simple to press while protecting against unexpected activation. Utilizing contrasting shades and appearances can boost presence and tactile feedback, assisting users in comparing secrets

Furthermore, the choice of materials plays an important role; top quality rubber compounds can boost durability and resistance to wear. It is also vital to take into consideration the assimilation of attributes such as backlighting and custom graphics, which can improve use in various environments.

Prototyping and individual testing are very useful in the style procedure, allowing for changes based on real-world responses. By adhering to these finest practices, makers can develop rubber keypads that not just look attractive however additionally satisfy the useful requirements of users successfully.

Frequently Asked Concerns

Just how Do I Choose the Right Rubber Product for My Keypad?

To choose the appropriate rubber product for a keypad, one must think about elements such as sturdiness, ecological resistance, tactile responses, and compatibility with the designated application, ensuring suitable performance and customer complete satisfaction in numerous problems.

What Are the Ecological Effects of Rubber Keypad Production?

Rubber keypad production can bring about ecological impacts such as logging for natural rubber resources, air pollution from chemical processes, and waste generation. Sustainable methods and products can reduce a few of these unfavorable results on communities.

Can Rubber Keypads Be Recycled or Reused?

Rubber keypads can be reused, but the process depends upon the details products utilized in their manufacturing. Recycling them in different applications is also feasible, contributing to squander reduction and promoting sustainability in manufacturing practices.

What Is the Ordinary Lifespan of a Rubber Keypad?

The typical life-span of a rubber keypad generally varies from 5 to one decade, relying on use, ecological factors, and upkeep. Normal care can extend its performance, while excessive wear might shorten its sturdiness.

Exist Any Kind Of Wellness Issues Associated With Rubber Keypad Products?

There are possible health and wellness issues connected to rubber keypad products, including allergies to specific chemicals and toxic irritants used in manufacturing. Proper handling and understanding of material make-up can mitigate these risks for users.

There are a number of kinds of rubber keypads, consisting of dome button keypads, which use a dome-shaped device that provides responsive comments when pressed. Selecting the appropriate products for rubber keypads is essential, as it straight affects their user, functionality, and sturdiness experience - Rubber Keypads. After identifying the appropriate materials for rubber keypads, strenuous screening procedures are executed to validate that the final products meet industry requirements and consumer expectations. Rubber keypad manufacturing can lead to environmental influences such as logging for all-natural rubber resources, contamination from chemical procedures, and waste generation. Rubber keypads can be recycled, yet the procedure depends on the particular products made use of in their production